lindarobin

Posts: 947

Joined: 8/28/2004

Status: offline

|

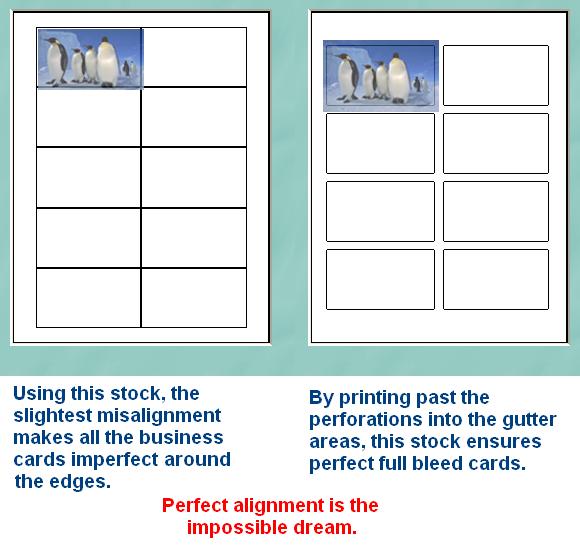

There is a good reason for the label templates to have a default white border. That is the safety zone that ensures your design and text fit within the label. If the labels on the sheet are flush against each other, printing to the edge will likely result in design overflow from one label onto its neighbours. The top image shows what you want; the bottom image shows what you may get.

It is near impossible to align the printing on your paper within one mm of the label edge every time. This is called printer feed variance. You can minimize the visual impact of printer feed variance by making the four edges the same colour or background.

Printer feed variance is not a concern if you print onto unformatted stock. By doing your own cutting, you can make sure your cuts are exactly on the edges.

If you still want to make full-bleed cards/labels on your pre-formatted stock, you will need to create a custom stock with the Custom Paper Wizard. (Read the Help menu's section on this subject.) One of the Wizard's steps will offer the full-bleed option. Check that box. When you are finished creating your custom paper, start a new project and select your new custom paper from the list.

Be advised. Printer feed variance is a fact. You may get one sheet printed perfectly and the very next sheet is off by a mm. This is within realistic expectations. Vibrations can cause the paper to slip a little to one side or the printer grabs the paper too hard on one side...

Attachment (1) Attachment (1)

< Message edited by Brandy redux -- 11/26/2009 4:07:37 PM >

|

Printable Version

Printable Version

New Messages

New Messages No New Messages

No New Messages Hot Topic w/ New Messages

Hot Topic w/ New Messages Hot Topic w/o New Messages

Hot Topic w/o New Messages Locked w/ New Messages

Locked w/ New Messages Locked w/o New Messages

Locked w/o New Messages Post New Thread

Post New Thread